Starch Polymerization Degree Determination

Based on the differing linkages of glucose molecules, starch is categorized into amylose and amylopectin. Amylose is primarily a linear polymer formed through α-1,4 glycosidic bonds between glucose units, whereas amylopectin consists of branched polymers created through both α-1,4 and α-1,6 glycosidic bonds. The chain length distribution of starch refers to the process of hydrolyzing starch’s 1,6-glycosidic bonds with isoamylase, resulting in glucan chains of varied lengths, and then the polymerization degree of the sample is analyzed by Ion Chromatography (IC) or Gel Permeation Chromatography (GPC) .

GlycoSpectra Analytics offers two analytical methods for determining the chain length distribution of starch: High-Performance Anion Exchange Chromatography with Pulsed Amperometric Detection (HPAEC-PAD or IC) and Gel Permeation Chromatography (GPC or SEC). HPAEC-PAD targets a measurement range of DP6-DP76, primarily assessing the branch lengths of amylopectin without reflecting the characteristics of amylose chains.In contrast, GPC spans a broader measurement range from dozens to thousands, accommodating the chain length distribution of both amylopectin and amylose. However, GPC’s accuracy diminishes for shorter chains, particularly those with a degree of polymerization (DP) of 10 or below.

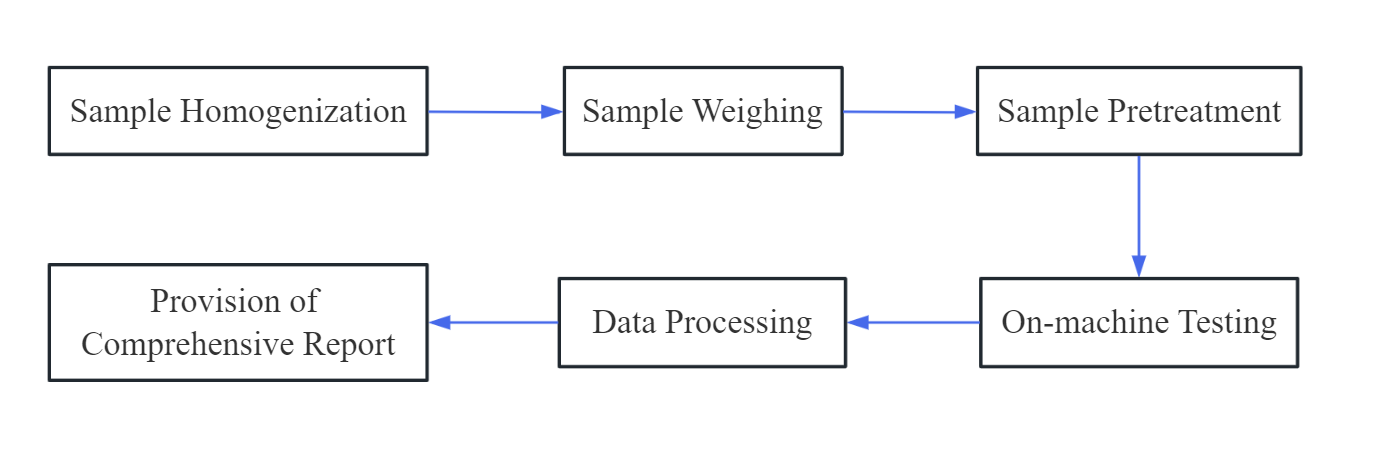

Workflow

Why Choose GlycoSpectra Analytics

1.Humanized solutions available, with both High-Performance Anion Exchange Chromatography and Gel Permeation Chromatography options.

2.Domestically leading, Gel Permeation Chromatography combined with DMSO system for analysis.

3.Professional and thorough service, with manual assistance in post-sale data interpretation.

Sample Submission Guidelines

1.Types of Samples

Starch samples, clients can provide the original sample for starch extraction by our company, which is subject to a separate charge.

2.Biological Replicates

A minimum of three biological replicates is recommended for robust results.

3.Quantity Requirements

Raw sample > 50 g; Starch >1 g.

4.Preparation Instructions

1)Establish both control and experimental groups, ensuring a minimum of three biological replicates.

2)Ensure maintain consistency in timing whenever possible.

3)Minimize preprocessing; we prefer to handle these steps. Clients should ensure liquid samples are securely packaged in non-glass containers and buffered against shock and impact. Dry solid samples can be untreated or preliminarily ground. Fresh solid samples require no treatment when shipped with ice packs at ambient temperature.

4)When shipping with dry ice, samples should be cut into small pieces, each less than 1 cm³.

5.Packing and Shipping

1)Store samples in clearly labeled tubes, label with sample name, concentration, and preparation date. Ensure tube tops are sealed.

2)For transport, secure sample tubes in 50ml capped centrifuge tubes placed in sealable bags. Use dry ice or ice packs for transportation, avoiding repeated freeze-thaw cycles. DO NOT send the samples out on Fridays, to avoid weekend delays.

6.Labeling Requirements

1)Employ double labeling, ensuring clear identification on both the sample tubes and external packaging.

2)To prevent confusion, avoid simplistic labels like A/B/C or 1/2/3. Instead, use a combination of letters and numbers for unique sample identification, reducing the risk of duplication.

7.Additional Information

A minimum of 24 analyses is required. If fewer than 24 analyses are conducted, the cost will be calculated as if 24 analyses were performed.